In the dynamic world of apparel manufacturing, staying competitive requires more than just fast production—it demands intelligence, adaptability, and sustainability.

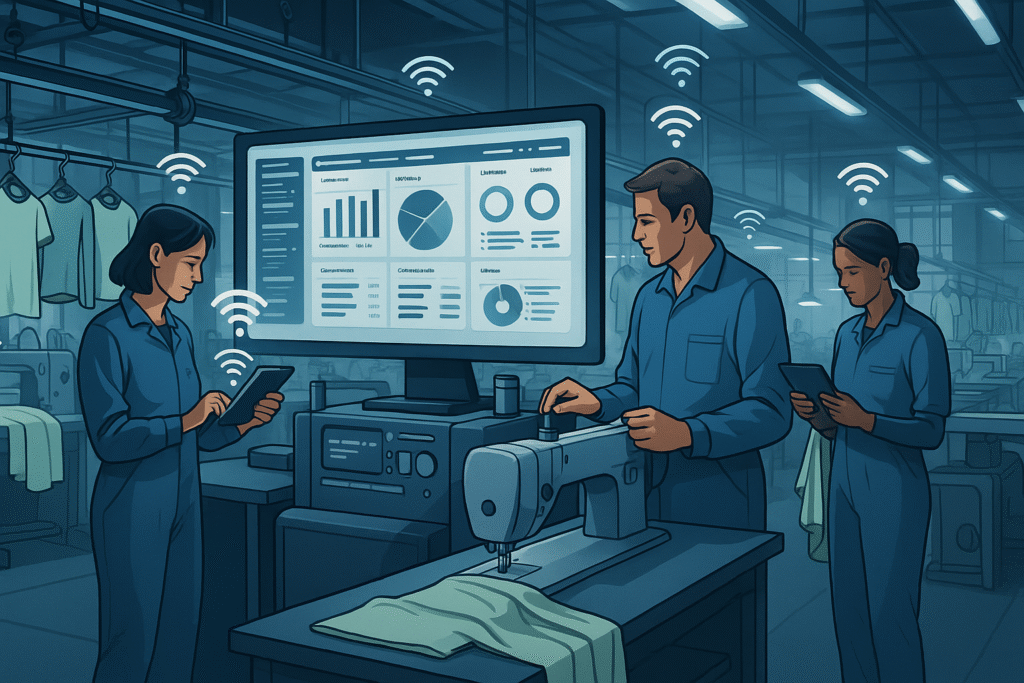

This is where the Industrial Internet of Things (IIoT) comes into play, transforming traditional apparel factories into smart, connected ecosystems. IIoT integrates sensors, machines, cloud platforms, and real-time data analytics to enable seamless communication across every stage of production. In an industry often plagued by overproduction, delayed maintenance, and inefficient workflows, IIoT offers a revolutionary solution. Apparel manufacturers can now monitor everything from machine uptime and environmental conditions to inventory levels and energy consumption. These smart systems not only deliver insights but can trigger automated responses, such as adjusting machine parameters when a fault is detected or sending alerts for predictive maintenance before a breakdown occurs. At SustainTex Solutions, we specialize in integrating IIoT technologies tailored to the apparel sector’s specific challenges. Whether it’s optimizing dyeing operations to reduce water waste or tracking real-time output on sewing lines to improve labor utilization, our solutions enable visibility and control like never before.

The benefits are immediate and multifaceted. Production lines become more agile, with automated scheduling systems that align machine availability with order deadlines. Downtime is reduced through condition-based monitoring, while quality improves due to early detection of defects. Moreover, data gathered from IIoT devices can be analyzed to identify trends, benchmark performance, and make informed decisions that enhance productivity. IIoT is also instrumental in sustainability—by tracking carbon emissions, water usage, and energy consumption, manufacturers can set and meet measurable environmental goals. For apparel companies aiming to meet ESG standards or qualify for green certifications, IIoT becomes not just a tool but a strategic enabler.

Furthermore, IIoT empowers manufacturers to localize production and support reshoring efforts. With smart systems in place, small to mid-sized U.S. factories can operate with the precision and efficiency needed to compete with offshore production. As global supply chains become more volatile, having local, data-driven operations ensures greater resilience and customer responsiveness. IIoT also supports worker safety by monitoring factory conditions in real time and alerting teams about unsafe environments. It enhances training through augmented reality systems and digital twin simulations, giving workers the tools to operate and maintain new technology confidently.

In essence, the future of apparel manufacturing lies in its ability to be both smart and sustainable. IIoT bridges this gap by transforming data into action, machines into intelligent assets, and factories into responsive environments. At SustainTex Solutions, our mission is to help manufacturers embrace this digital revolution, one smart system at a time. Through tailored implementation, workforce training, and continuous analytics, we make sure that our clients aren’t just keeping up—they’re leading the change.