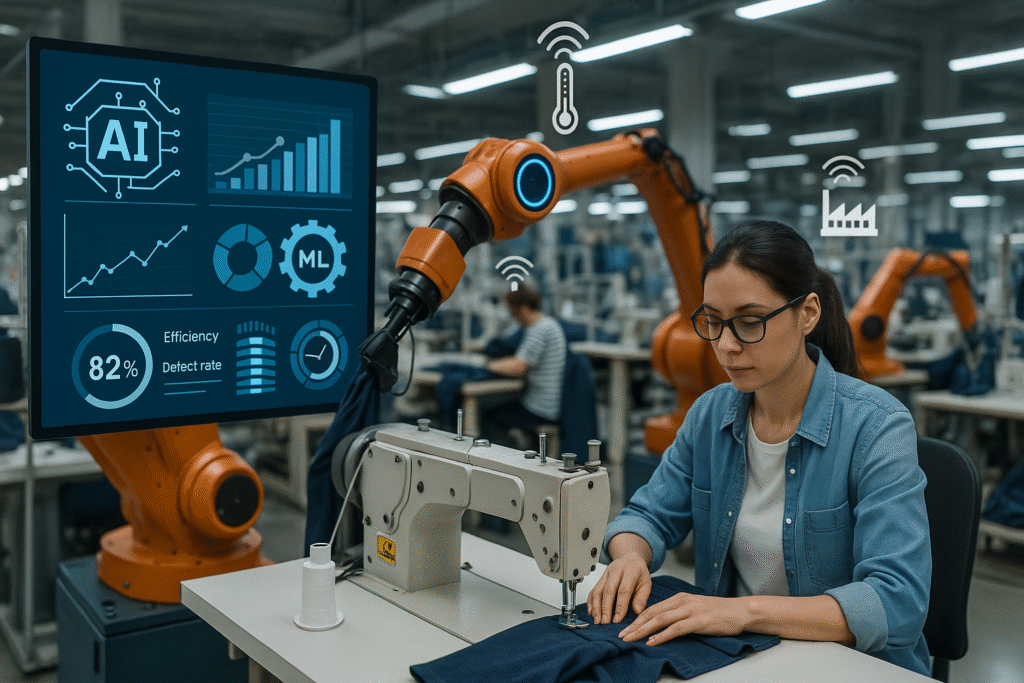

The transition to Industry 4.0 is redefining how apparel manufacturers operate, and at the heart of this evolution are artificial intelligence (AI) and machine learning (ML). These technologies are more than just buzzwords—they are transforming factories into intelligent, self-learning systems capable of adapting to real-time data and evolving market conditions. In an industry driven by time-sensitive orders, complex supply chains, and high-volume customization, traditional decision-making often leads to inefficiencies and missed opportunities. Data-driven manufacturing changes that paradigm. By integrating AI and ML into the production environment, apparel manufacturers can analyze massive volumes of historical and real-time data to predict machine failures, fine-tune resource planning, optimize schedules, and reduce waste—resulting in higher profitability, improved quality, and faster turnaround times.

At SustainTex Solutions, we specialize in helping manufacturers implement AI-powered tools that deliver measurable operational gains. One of the most impactful use cases is predictive maintenance. Rather than relying on fixed service schedules or reacting to breakdowns, machine learning algorithms continuously analyze sensor data to forecast when a machine is likely to fail. This allows for timely interventions, reduced downtime, and lower maintenance costs. Another key area is demand forecasting and production planning. Using AI, we build models that account for seasonal trends, customer behavior, and raw material availability to generate accurate predictions—empowering manufacturers to make proactive decisions on procurement, inventory, and capacity utilization.

AI also enhances quality assurance by leveraging image recognition and anomaly detection algorithms to identify defects in real time. Instead of manual inspections that vary in accuracy, smart vision systems monitor every garment on the line, flagging inconsistencies immediately. This minimizes rework, improves first-pass yield, and ensures a consistent customer experience. Machine learning can also support lean operations by analyzing data across production lines to highlight inefficiencies, pinpoint bottlenecks, and suggest workflow improvements. Through unsupervised learning, even hidden patterns that human managers might overlook are brought to light.

In addition to operations, AI plays a critical role in sustainability and compliance. Data analytics platforms track energy use, water consumption, and carbon emissions, enabling manufacturers to meet ESG targets and industry regulations with confidence. Dashboards powered by tools like Python, Power BI, or Tableau provide actionable insights that factory managers can use to make data-backed decisions at every level of the supply chain. As global supply chain volatility increases, such agility and foresight become crucial assets.

Importantly, the integration of AI does not replace the human workforce—it enhances it. With proper training, employees become analysts and decision-makers rather than task executors. At SustainTex Solutions, we provide not only the technological infrastructure but also capacity-building programs to ensure a successful human-machine collaboration. Data-driven manufacturing is no longer the future—it’s the present reality for factories that want to thrive in the digital age. By embracing AI and machine learning, apparel manufacturers can position themselves at the forefront of efficiency, innovation, and sustainability.