Across the U.S. manufacturing landscape, factories are navigating a perfect storm of rising labor costs, tightening margins, and increasing customer expectations. In this high-pressure environment, Six Sigma has emerged as one of the most effective methodologies for achieving operational excellence while simultaneously cutting costs. Rooted in statistical analysis and process control, Six Sigma provides a structured framework to identify inefficiencies, eliminate defects, and bring consistency to even the most complex manufacturing systems. As factories adopt this methodology and integrate it with real-time analytics and modern tools, the result is measurable cost savings, improved product quality, and enhanced customer satisfaction.

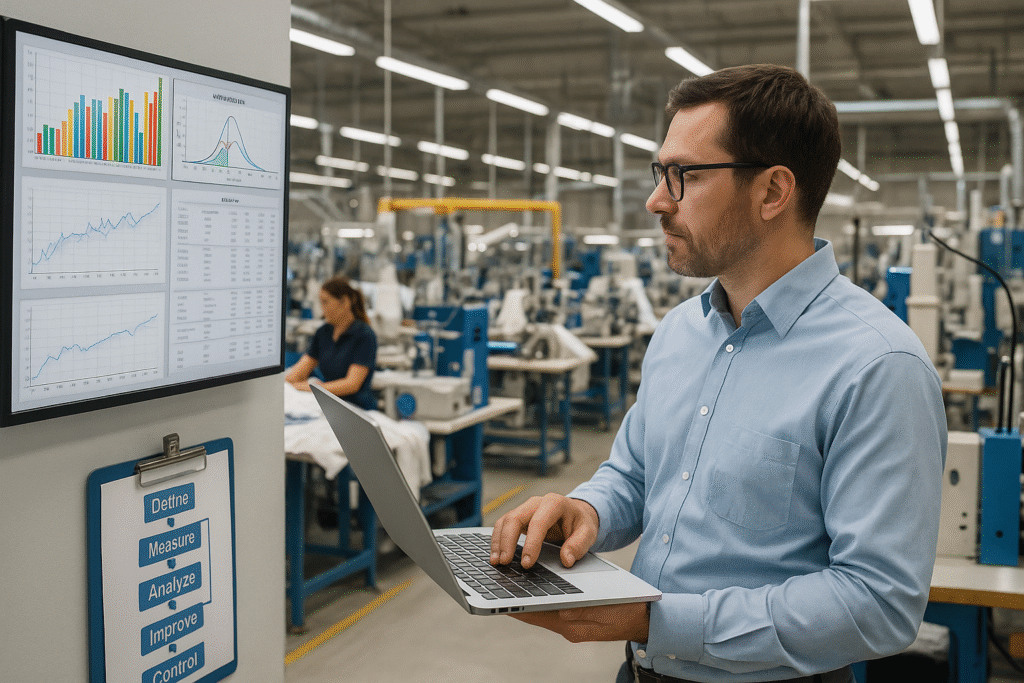

At its core, Six Sigma is focused on reducing variation within manufacturing processes. By applying the DMAIC framework (Define, Measure, Analyze, Improve, Control), manufacturers can systematically investigate problems, pinpoint root causes, and implement long-term solutions. Instead of relying on guesswork, decisions are backed by data — enabling teams to make precise, confident changes that improve process stability. For instance, in a textile factory facing recurring defects in stitching or dye quality, a Six Sigma approach would help isolate the root cause — be it a machine calibration issue, operator error, or raw material inconsistency — and implement controls to prevent reoccurrence. By reducing variation, companies produce fewer defects, less rework, and more predictable output — all of which contribute directly to cost reduction.

One of the greatest strengths of Six Sigma is its ability to integrate with modern factory technologies, especially in the era of Industry 4.0. When combined with real-time analytics, IoT sensors, and cloud-based monitoring systems, Six Sigma becomes exponentially more powerful. Continuous data streams from the shop floor allow for near-instant feedback on process performance. Engineers can track variables like temperature, machine speed, material quality, and defect rates in real time — allowing them to detect trends before they become costly problems. By proactively addressing potential issues, manufacturers can minimize downtime, reduce scrap, and streamline production cycles.

Cost reduction through Six Sigma goes beyond quality improvements. The methodology enables better resource utilization by identifying bottlenecks, redundancies, and underperforming assets. For example, a Six Sigma analysis of equipment effectiveness might reveal that certain machines are idle for longer than expected due to inefficient job scheduling. With this insight, managers can adjust workflows, optimize maintenance intervals, or consolidate operations — resulting in lower overhead and increased asset productivity. Similarly, inventory analysis using Six Sigma tools can uncover overstocked or slow-moving items, enabling better demand forecasting and supply chain planning.

Moreover, Six Sigma contributes to cultural transformation within factories. It empowers employees at every level to contribute to process improvement, backed by training, tools, and a shared language of quality. Teams become more collaborative, problem-solving becomes data-driven, and continuous improvement becomes embedded in the organization’s DNA. This cultural shift not only sustains cost savings over time but also drives innovation and agility in a competitive market.

In conclusion, Six Sigma is far more than a quality control technique — it is a strategic cost-reduction engine for U.S. factories. As manufacturers aim to compete globally while operating domestically, Six Sigma provides a roadmap for doing more with less — minimizing waste, maximizing efficiency, and delivering consistent, high-quality products. When applied effectively, it transforms manufacturing operations from reactive to resilient, from inconsistent to world-class.